Welcome to Our Website !

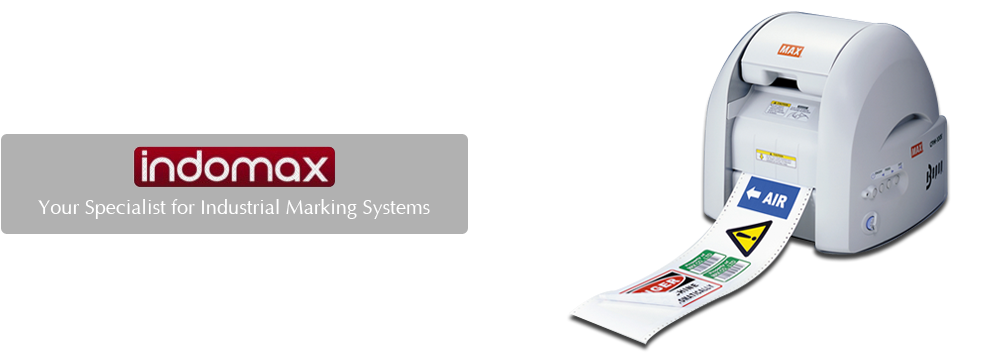

Offering a precision engineered range of Label Printing Machine, Ferrule Printer Machine, Printing Machine, Ferrule Printing Machine, Label Printing Machine, Consumables for CPM- 100, Economical Ink Ribbon, etc.

Company Overview

By making use of quality tested raw materials and ultra modern machinery in the production process have helped us deliver a range of superior grade products including Sticker Printer Machine, Coil Nailer, Inkjet Printer, etc. Rigorous quality checks of offered products along various quality parameters has helped us ensure that they comply with international quality norms and guidelines. We have thus been able to consistently deliver superior quality to customers. With the assistance of our team of experienced professionals, we are capable of delivering these qualitative products to clients at market leading prices, within the stipulated time frame. The efficacy of our R&D unit's at upgrading our product range has helped us stay ahead of our competitors and ensure that our customers always have access to the very best in the market.

|

Company Profile |

|

|

Business Type |

Supplier Manufacturer |

|

Year of Establishment |

1997 |

|

Ownership Type |

Partnership |

|

Major Markets |

Indian Subcontinent |

|

Total Number of Employees |

11 to 25 People |

|

Quality Measures/Testing Facilities |

Yes |

|

Customized Packaging |

Yes |

|

Payment Mode |

Cash Cheque |

Product Portfolio

Under

the guidance and leadership of 'Mr. Shashikant S. Joshi', who possesses

extensive knowledge and experience in the field, we have been able to

grow as an organization and emerge as a pioneer in the market with our

quality products. His sharp business acumen along with ethical business

transactions have helped us gain prominence in the industry and gain the

trust of our customers.

We are a leading firm, known in the

industry for our proficiency in manufacturing and supplying a

defect-free range of Industrial and Electronic Equipment &

Components. Our product range encompasses Ferrule Spares, Ruling

Machines, Ink Ribbon, Sticker Printing Machine, Economical Ink Ribbon

and Electronic Lettering Machine. These machines and components are

manufactured using premium grade raw material, under the strict

supervision of our quality analysts and hence, these are in accordance

with international quality norms and guidelines. Our product range

scores high on various quality parameters, which are listed below:

- Dimensional accuracy

- Efficiency

- Optimum performance

- Durability

- Corrosion & abrasion resistance

- Wear & tear resistance

Our Team

Our organization has an adept team of professionals, which has a remarkable amount of experience in this industry. These professionals handle the varied processes efficiently, which help us in achieving our common goal of providing an utmost level of satisfaction to the clients. Our professionals are highly receptive and possess a deep understanding of the industry owing to which they are able to cater to customer specific requirements. Furthermore, the product designers at our firm endeavor to deliver innovative & feasible designs that are precision-engineered, flameproof and in keeping with industrial standards. Our dexterous researchers work hard on their part to provide our clients with customized solutions. We have the following professionals in our team:

- Engineers

- Technicians

- Quality inspectors

- Marketing & sales personnel

- Warehousing & packaging professionals

Quality forms the core base of our organization and hence, we implement strict quality measures during different stages of our production process, which help us to deliver top-notch quality Industrial and Electronic Equipment & Components, Sticker Printing Machine and many more. The raw material for our products undergoes various quality checks and inspections to ensure its accordance with IS quality standards. Furthermore, the entire manufacturing process is done under the supervision of our quality experts. Quality tests that are performed on our products are as follows:

- Strength test

- Dimensional accuracy test

- Efficiency test

- Durability test

- Weathering effect test

- Performance evaluation test

Our organization has a well-equipped infrastructure facility, which aids in delivering high-quality Industrial and Electronic Equipment & Components. It has all the high-tech and advanced machinery & equipment required for providing a defect-free range of machines and components to our clients. The facility has been divided into separate departments that handle individual phases of production. Each department is managed by a team of highly skilled professionals who possess in depth knowledge and rich experience in the field. The various subunits at our manufacturing facility includes:

- Manufacturing unit

- Quality control unit

- R&D unit

- Warehousing & packaging unit

Warehousing & Packaging

To

store our product range, our organization has developed a

state-of-the-art and advanced warehousing unit. The huge storage

capacity of our warehouse helps in storing the bulk and urgent

requirements of our customers. Furthermore, our warehouse is segregated

into several units that facilitate easy access and retrieval of our

products. Good connectivity of our warehouse with roads and ports helps

us to deliver the consignments within the promised time.

High-grade packaging material is used to pack our equipment and components, which helps in ensuring their safely delivery.

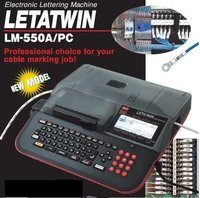

High Speed Marking

- LM-390A has an enhanced feeding and half-cutting system that delivers marking speed at 35mm/second.

- LM-390A features USB port that is used for direct connection with Windows personal computer, as well as USB memory slot for off-the-line data exchange with PC using "LETATWIN PC EDITOR"

- LM-390A is capable of manufacturing 50pcs of 20mm-length tube per minute.

- Maximum 100,000 characters : built-in large memory storage

- Easy access from PC using USB

Client Satisfaction

Our

organization is focused upon achieving the highest level of customer

satisfaction and in order to fulfill this commitment, we ensure high

quality and efficiency in all our machines and components. We persevere

and try to understand the changing market trends and the advancements in

technology in this field, in order to know and comprehend the specific

requirements of our valued customers'. Speedy and timely delivery of

products has led to positive responses from clients. We have been

consistently delivering superior quality with our product range and are

today catering to the demands of diverse sectors. Moreover, for the ease

and convenience of our valued customers, we provide them with easy

payment modes like cash, cheque, etc., and ensure that they remain

updated regarding the progress of their orders.

Why Us?

Our

organization is one of the leading providers of Industrial and

Electronic Equipment & Components of flawless quality. Furthermore,

competitive pricing of these qualitative products helps us stay ahead of

our competitors. Timely delivery, ethical business policies and

customized packaging of our products are some of the factors that have

helped us gain prominence in the industry.

- Products backed by R&D support system

- Wide distribution network

- Team of experts

- Compliance to business ethics

- Customized range

- Timely delivery

- Competent team of workforce.

Our Team

Our organization has an adept team of professionals, which has a remarkable amount of experience in this industry. These professionals handle ...

Quality Assurance

Quality forms the core base of our organization and hence, we implement strict quality measures during different stages of our production...

Infrastructure Facility

Our organization has a well-equipped infrastructure facility, which aids in delivering high-quality Industrial and Electronic Equipment & Components... |